Tailor-Made for Various Customizations

Chopped fiber is a processed carbon fiber product made by bundling carbon fibers with a sizing agent and cutting them to specific lengths. As a filler that imparts advanced functionalities such as electrical conductivity and thermal conductivity, it is primarily used in compounds with thermoplastic resins and supports a wide range of other applications.

At Nippon Polymer Sangyo, tailor-made customization is available. Our sizing agent lineup includes urethane, epoxy, acrylic, and others, allowing selection to match various matrix resins. Additionally, we can control the sizing agent adhesion rate and cutting length.

Our raw materials are production remnants generated during the manufacturing and molding processes of major carbon fiber manufacturers. We purchase materials from carbon fiber manufacturers not only in Japan but also around the world—including leftover rolls from production, materials with fine fuzz, lot remainders, and items with appearance defects—that would otherwise be discarded. Since these are not recycled products, they maintain virgin quality equivalent to regular products.

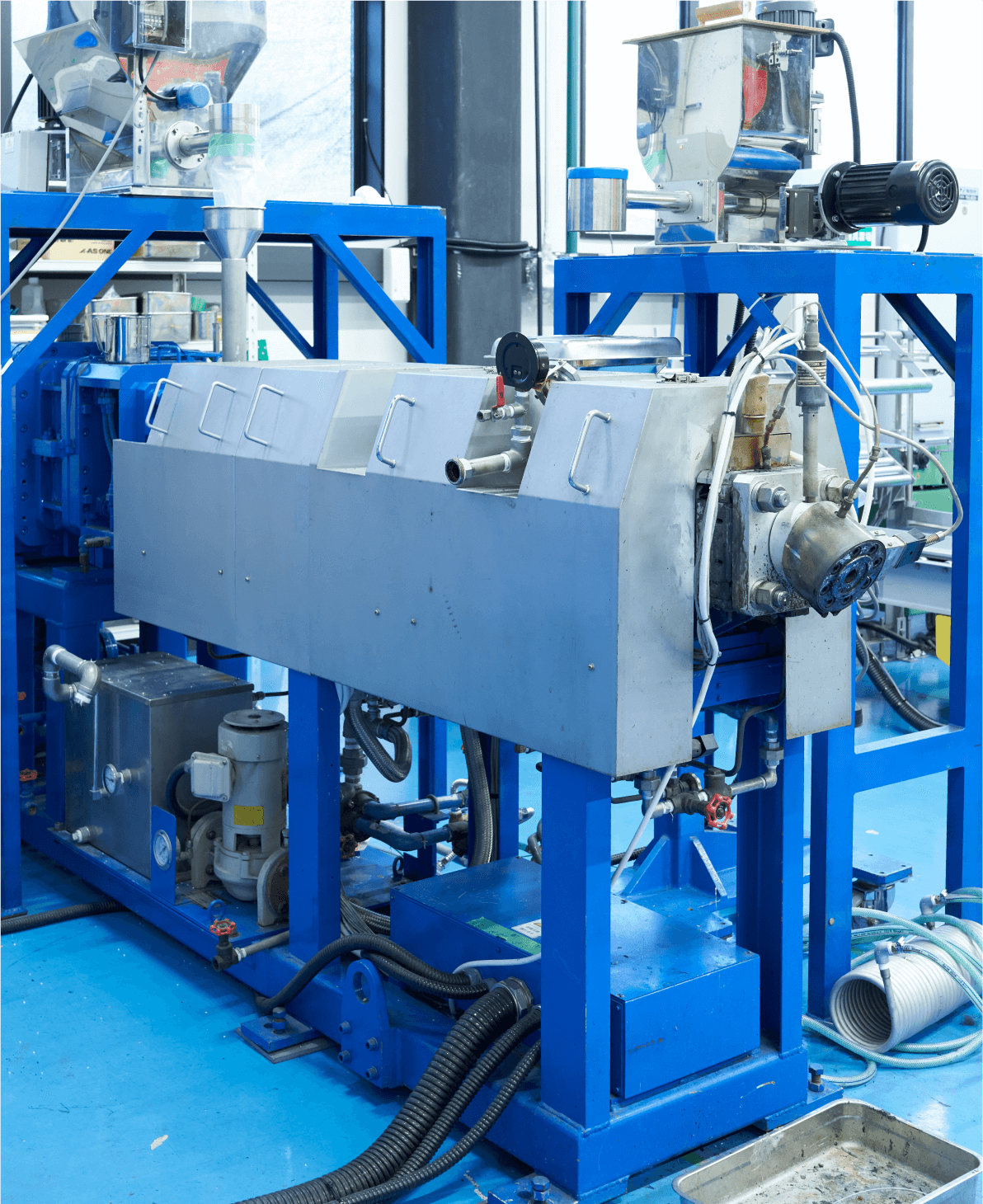

At Nippon Polymer Sangyo, we accept compound test orders starting from small quantities. We support a wide range of thermoplastic resin compounds, from commodity plastics to super engineering plastics. We have carbon fibers in stock, and with our extensive connections with resin manufacturers, we can also source materials you specify. Additionally, we provide mechanical property data at reasonable prices. Furthermore, we can supply samples for prototype molding, so please feel free to contact us.

Milled fiber is a processed carbon fiber product made by grinding PAN-based carbon fibers, applying short fiber cutting technology. Like chopped fiber, it serves as a filler that imparts advanced functionalities and is used in various applications including compounds with thermoplastic resins, sliding components, friction materials, and rubber products. Even as a grinded product, it maintains its fiber shape, enabling improvements in strength and elastic modulus.

We currently offer three types of standard grades, including those containing recycled materials, but fiber length can be controlled as desired beyond these options. We will propose the optimal solution suited to your application.

| Grade | Average Fiber Length (μm) | Bulk Density (g/ml) | Sizing Amount (wt%) |

|---|---|---|---|

| CFMP-30 | 30 - 50 Av. | 400 - 500 | 0 - 0.5 |

| CFMP-150 | 90 - 110 | 450 - 550 | 0 - 0.5 |

| CFMP-150RE | 100 - 130 | 350 - 500 | 0 - 0.5 |

| Grade | CFMP-30 |

|---|---|

| Average Fiber Length (μm)< | 30 - 50 Av. |

| Bulk Density (g/ml) | 400 - 500 |

| Sizing Amount (wt%) | 0 - 0.5 |

| Grade | CFMP-150 |

|---|---|

| Average Fiber Length (μm) | 90 - 110 |

| Bulk Density (g/ml) | 450 - 550 |

| Sizing Amount (wt%) | 0 - 0.5 |

| Grade | CFMP-150RE |

|---|---|

| Average Fiber Length (μm) | 100 - 130 |

| Bulk Density (g/ml) | 350 - 500 |

| Sizing Amount (wt%) | 0 - 0.5 |

Values are for reference. Please contact us if you require specifications other than those listed above.