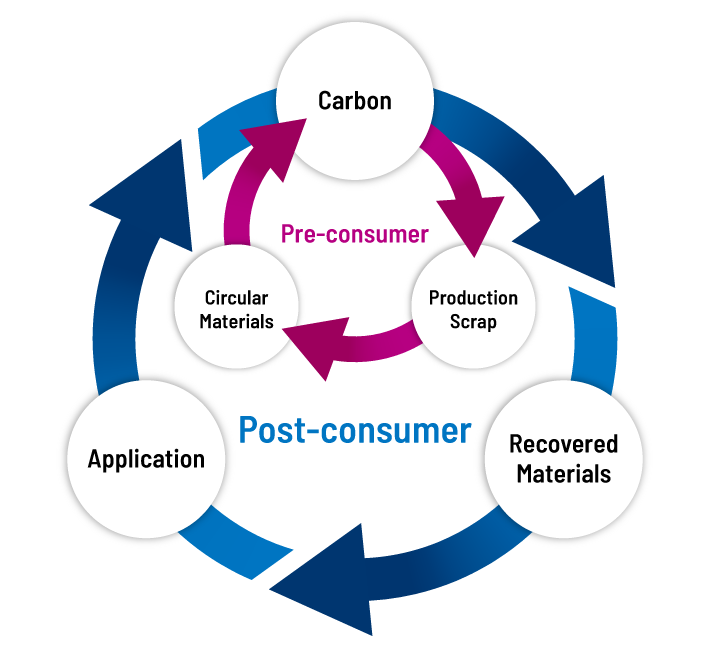

Building the Cycle of Effective Utilization Together

Not just reusing, but building new applications

Post-consumer waste such as used products containing carbon fiber, non-conforming items, and scrap generated during manufacturing processes. By extracting only the carbon fiber from such post-consumer materials and reusing it, we aim not only to reduce environmental impact but also to build new business opportunities.