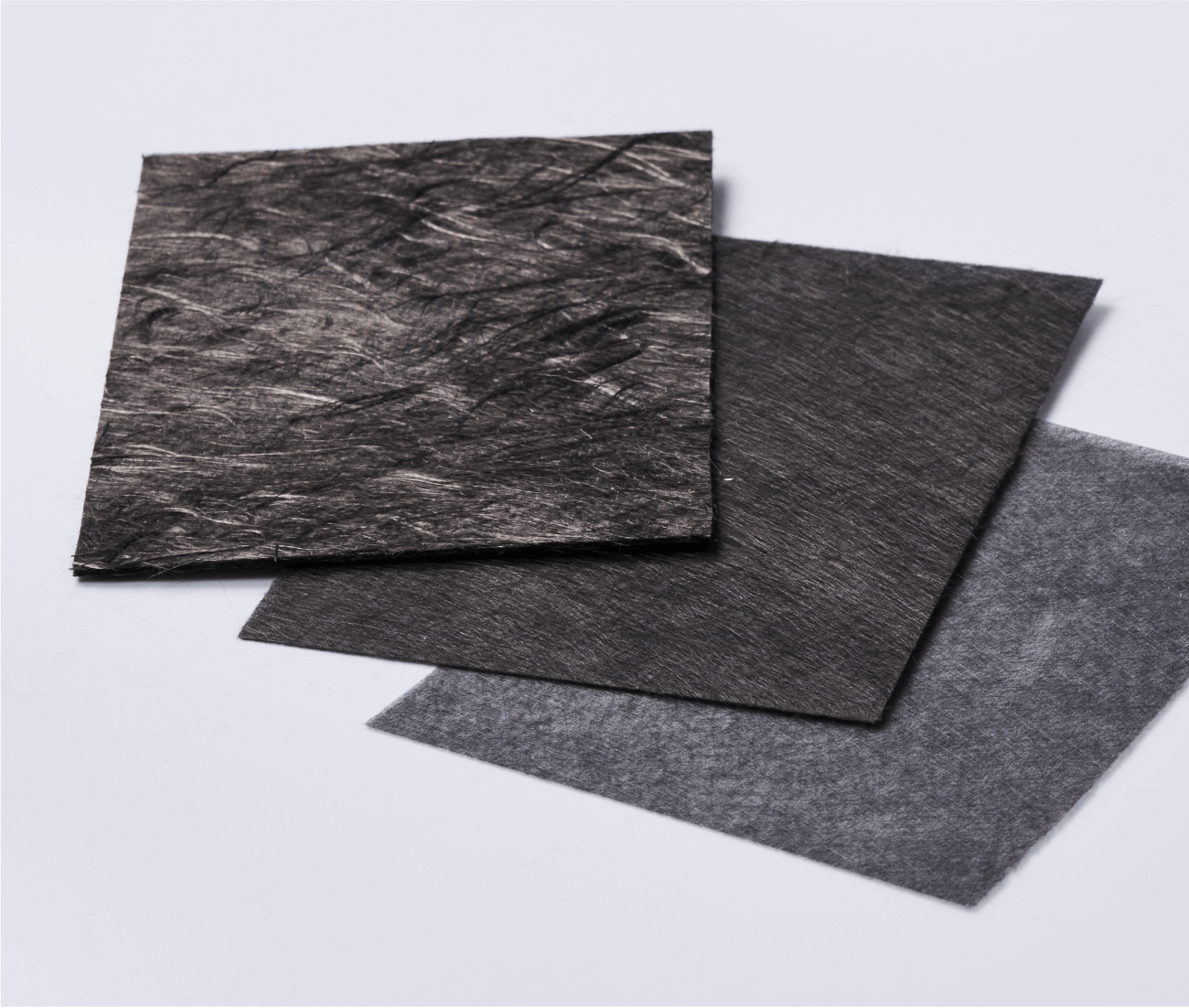

Paper is a processed carbon fiber product created by using the wet-laid method to form sheets from chopped fiber (a papermaking technique similar to making Japanese washi paper), with fibers oriented two-dimensionally. It offers excellent chemical resistance, heat resistance, electrical conductivity, and electromagnetic shielding properties, while also possessing high strength and dimensional stability.

We control the type (polyester or polyvinyl alcohol) and amount of binder used during the papermaking process according to your requirements.

Additionally, we are developing sheet-form molding materials (CFRTP paper) that combine carbon fiber and thermoplastic resin fiber. For details on our products under development, please feel free to contact us.

This is a low-weight paper with carbon fibers dispersed in an individual, separated state. It can be used to improve the surface properties (smoothness and paintability) of composites.

| Grades | Weight (g/m²) | Binder/Amount |

|---|---|---|

| CFP-030PE | 30g/㎡ | PE Binder 20% |

| CFP-030PV | 30g/㎡ | PVA Binder 20% |

| CFP-010PV | 10g/㎡ | PVA Binder 20% |

| Grades | CFP-030PE |

|---|---|

| Weight (g/m²) | 30g/㎡ |

| Binder/Amount | PE Binder 20% |

| Grades | CFP-030PV |

|---|---|

| Weight (g/m²) | 30g/㎡ |

| Binder/Amount | PVA Binder 20% |

| Grades | CFP-010PV |

|---|---|

| Weight (g/m²) | 10g/㎡ |

| Binder/Amount | PVA Binder 20% |

This is a high-weight paper made by forming sheets while retaining carbon fiber bundles in their unopened state. It also offers excellent machinability. Additionally, it can be used as a core material as an alternative to over-spec products, leading to cost reduction.

| Grades | Weight (g/m²) | Binder/Amount |

|---|---|---|

| CFZ-200RD | 200g/㎡ | PVA Binder 5% |

| Grades | CFZ-200RD |

|---|---|

| Weight (g/m²) | 200g/㎡ |

| Binder/Amount | PVA Binder 5% |

Felt is a processed carbon fiber product created by orienting chopped fiber three-dimensionally using the dry method (needle punch) to form a nonwoven fabric. It offers excellent heat resistance and experiences almost no degradation even when used at high temperatures. It is also an advantageous material for thick molding applications.

In addition to manufacturing with 100% recycled carbon fiber and blending carbon fiber with rayon fiber, combinations of carbon fiber with various thermoplastic resin fibers are possible.

We offer tailor-made proposals for "CFRTP felt," a sheet-form molding material that combines carbon fiber with thermoplastic resins such as nylon, PPS, PP, and polycarbonate.

| Grades | Weight (g/m²) | Binder/Amount |

|---|---|---|

| CFF-500 | 500g/㎡ | CF 80% + Rayon Fiber 20% |

| CFF-1000 | 1,000g/㎡ | CF 80% + Rayon Fiber 20% |

| CFZ-500SD | 500g/㎡ | CF 100% |

| Grades | CFF-500 |

|---|---|

| Weight (g/m²) | 500g/㎡ |

| Binder/Amount | CF 80% + Rayon Fiber 20% |

| Grades | CFF-1000 |

|---|---|

| Weight (g/m²) | 1,000g/㎡ |

| Binder/Amount | CF 80% + Rayon Fiber 20% |

| Grades | CFZ-500SD |

|---|---|

| Weight (g/m²) | 500g/㎡ |

| Binder/Amount | CF 100% |